THIS IS NOT A TOY BUT IT COULD BE

This object is not a toy. It is a political statement and a call to realign parts of the EU’s legislative and funding framework with the realities of 21st-century making, community-based production and the right to repair and reuse.

Today, current CE certification rules were conceived for centralised, industrial production lines rather than for decentralised, digital and distributed manufacturing. The consequence is clear: innovation is slowed, circularity is penalised, and local regenerative production is legally constrained, especially for small producers, communities and commons-based initiatives. Yet the technologies driving the ecological and digital transitions demand regulatory frameworks that are agile, open and participatory – capable of empowering citizens, workers and local ecosystems instead of locking them out of advanced manufacturing.

This object is not a toy. It is a conceptual manifesto.

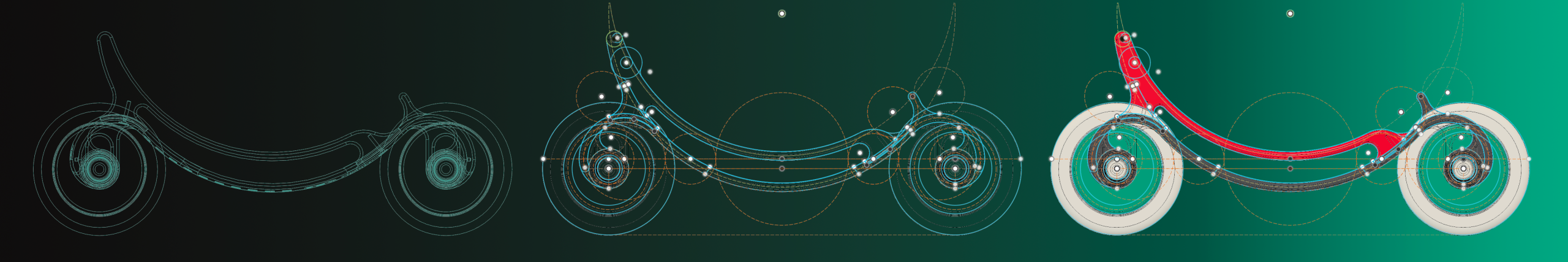

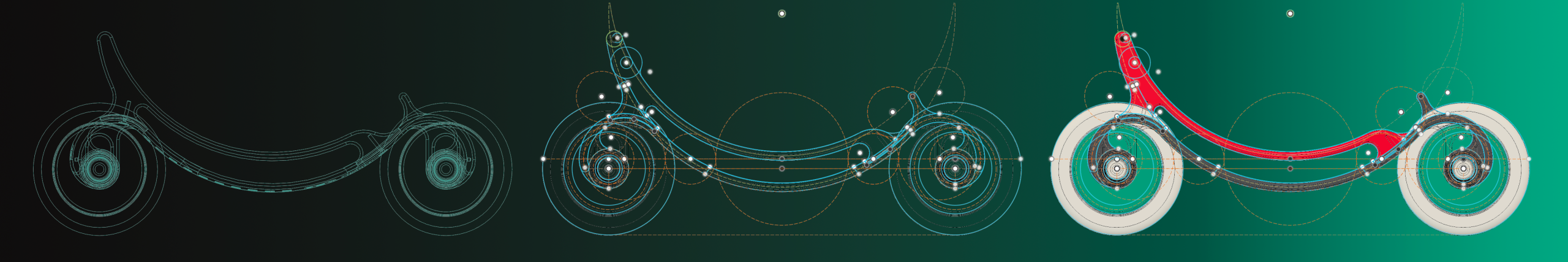

Designed entirely by myself1 and inspired by the mathematical studies and artworks of Luca Pacioli and Leonardo Fibonacci on the Golden Ratio2, this object – which I have named Phibocycle 618 – combines new digital technologies, sustainability and artistic expressions rooted in Europe’s cultural heritage.

Why is this not a toy – but could be?

This minimalist 3D-printed quadricycle exposes a growing paradox in European legislation: today, it is disproportionately difficult to place 3D-printed objects on the EU market. This object is one of the outputs of a third-party Horizon 2020 experiment, and yet it cannot easily be brought to market – like many other 3D-printed products, including not only toys, but also spare parts, construction products, medical devices and so on. EU rules were largely conceived for traditional, centralised industrial production, not for the kind of innovation, design flexibility, personalisation and empowerment of SMEs, makers and prosumers that additive manufacturing makes possible.

It is not a toy. It is a call to action.

In relation to these issues, I intend, at the beginning of the new year, to send the attached letter “Strengthening the EU additive manufacturing sector by improving regulatory frameworks and targeted R&D support” to the attention of Commissioners Teresa Ribera, Vice-President for Clean, Just and Competitive Transition; Ekaterina Zaharieva, Startups, Research and Innovation; Valdis Dombrovskis, Economy and Productivity Implementation and Simplification; and Stéphane Séjourné, Prosperity and Industrial Strategy.

I am also in the process of organising an event on this topic, bringing together experts and stakeholders from the sector, representatives of the European Commission and policy-makers, with particular attention to the grey areas within the current European legislative framework and their implications for competitiveness, industrial development, job creation and a just, green and socially fair transition.

You will receive an email asking whether you would be interested in co-signing the letter and taking part in the event, so that we can build a broad, cross-sectoral coalition for a more democratic and inclusive approach to advanced manufacturing in Europe. In the meantime, I wish you a very happy holiday season.

Kind regards,

Brussels, 10 December 2025

Dario Tamburrano

1) It is part of the results (one of the deliverables) of the toys4humanity project, funded through the Horizon 2020 AMable D637 cascade funding scheme. The AMable consortium, coordinated by Fraunhofer ILT, received support from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 768775. https://www.toys4humanity.eu/. Intellectual property is protected

2) Luca Pacioli: https://en.wikipedia.org/wiki/Luca_Pacioli. Leonardo Fibonacci: https://en.wikipedia.org/wiki/Fibonacci. Golden Ratio (1,618): https://en.wikipedia.org/wiki/Golden_ratio#History

STRENGTHENING THE EU ADDITIVE MANUFACTURING SECTOR

BY IMPROVING REGULATORY FRAMEWORKS AND TARGETED R&D SUPPORT

To the attention of Commissioners:

• Teresa Ribera, Vice-President for Clean, Just and Competitive Transition of the European Commission

• Ekaterina Zaharieva, Startups, Research and Innovation

• Valdis Dombrovskis, Economy and Productivity Implementation and Simplification;

• Stéphane Séjourné, Prosperity and Industrial Strategy

As the Additive Manufacturing (AM) industry continues to evolve, it is increasingly evident that it already plays a pivotal role in Europe’s industrial and technological future – a role that could become even more significant if the EU addresses existing barriers to market access. AM is not just an innovative production method, but a transformative technology that can reduce costs, accelerate innovation and have a substantial, positive impact on key European sectors such as medical and biotech, aerospace, energy, defence and automotive manufacturing. At the same time, if steered by appropriate public policies, AM can contribute to a more sustainable, resilient and socially just industrial model by enabling shorter supply chains, supporting quality jobs in local communities and fostering more democratic access to advanced manufacturing capabilities across Europe.

Despite the EU’s strong position in AM research and innovation, global competition is accelerating, with the US, China and other countries strategically placing AM at the core of their industrial policies. To ensure that Europe maintains its leadership, preserves its strategic autonomy and supports the reshoring of critical supply chains in an increasingly tense geopolitical context, it is imperative that the next EU R&D framework programme prioritises AM as a critical enabling technology. At the same time, this must be done in a way that aligns with the Union’s social, environmental and cohesion objectives – ensuring that AM contributes to quality jobs, fair working conditions, reduced inequalities between regions and a just transition for workers and communities affected by industrial change.

While the EU has supported AM through framework programmes such as FP7, Horizon 2020 and Horizon Europe, further efforts are needed to bridge existing gaps and fully unlock the potential of this technology in the public interest. For example, some legislative and certification-related barriers still hamper the wider uptake of AM in many sectors especially for SMEs and local production ecosystems. We therefore strongly urge the Commission to consider the following four priorities in the design of the upcoming EU R&D framework programme, ensuring at the same time that support for AM is closely linked to climate objectives, and social and territorial cohesion.

Establish a Public-Private Partnership (PPP) on additive manufacturing. A European PPP dedicated to AM would serve as a collaborative platform bringing together industry leaders, research institutions, SMEs, workers’ representatives and policy makers. Similar to the “America Makes” initiative in the US (americamakes.us), such a partnership would drive research, certification, standardisation, industrial adoption and workforce development, while also facilitating knowledge transfer and cohesion across EU Member States. By supporting pre-competitive research on material properties and sustainability , process reliability and quality assurance, the partnership would help to establish clear certification pathways, thereby reducing the time and cost required for companies – in particular SMEs and local producers – to bring AM products to market, while promoting quality jobs, fair working conditions and environmentally responsible industrial practices.

Build on the outcomes of EU-Funded projects. The EU has already invested significantly in AM through projects under Horizon 2020 and Horizon Europe. However, many successful project results remain underused due to a lack of structured follow-up initiatives and insufficient support for their uptake by SMEs, public services and local production ecosystems. To fully leverage these past investments in the public interest, the Commission should establish mechanisms to ensure that project results are translated into industrial applications, scale-up opportunities and further innovation cycles, and that their findings are taken into account in upcoming legislative proposals, such as the revision of the Medical Devices Regulation. This includes developing initiatives that facilitate the integration of AM innovations arising from EU-funded research, while ensuring alignment between completed projects and future funding priorities. In addition, past project results offer a strong foundation to support standardisation efforts and application-specific standards. Strengthening such standardisation frameworks would enable wider adoption of AM, create synergies with existing industrial technologies and position European industries at the leading edge of global competition while contributing to quality jobs, fair working conditions and a just transition across regions.

Expand cascade funding for AM to reach more micro and small enterprises. While AM has demonstrated its potential in high-value sectors, its adoption across the broader EU industrial landscape, particularly among SMEs, cooperatives and local production ecosystems, remains limited. Expanding cascade funding mechanisms dedicated to AM would enable a wider range of actors to participate in R&D projects, fostering innovation and the integration of AM technologies at all levels of the supply chain, and ensuring that they are embedded into diverse and more localised production networks. By lowering financial barriers, the EU can stimulate entrepreneurship, accelerate the uptake of AM technologies so contributing to quality jobs in Europe.

Promote scale-up of additive manufacturing through coordinated EU-level support. To fully capitalise on Europe’s strong AM research base, greater emphasis must be placed on supporting the scale-up and wider deployment of mature and sustainable AM technologies. The European Innovation Council (EIC) should play a central role in facilitating this transition by supporting large companies as well as SMEs and other innovation actors in bringing proven solutions to industrial scale. This includes helping innovators and creators to navigate the challenges of market entry, production ramp-up and integration into existing manufacturing ecosystems while ensuring that workers and local communities also benefit from these transformations.

Furthermore, coordinated action across EU funding instruments – such as the EIC, the Digital Europe Programme, Cohesion Policy Funds and InvestEU – is needed to ensure that promising technologies such as AM can be widely adopted across regions and sectors, including in less-developed and transition regions. By aligning funding strategies and providing targeted support for the demonstration, roll-out and replication of AM solutions, the EU can foster a more resilient and competitive manufacturing base, especially among SMEs and mid-caps. Such coordination will also help to close regional innovation gaps and ensure a more balanced uptake of AM technologies across the Union.

Address legislative barriers to market access. Today, it is disproportionately difficult to place 3D-printed objects on the EU market because current CE certification rules were conceived for centralised, industrial production lines rather than for decentralised, digital and distributed manufacturing. This situation makes it hard, even for EU-funded project results, to actually reach the market, and also prevents the economically viable production of small series of highly customisable products tailored to specific needs. The consequence is clear: innovation is slowed, circularity is penalised, and local regenerative production, community-based manufacturing and quality job creation are legally constrained, with negative impacts that are felt most acutely by SMEs, local producers and citizens who could benefit from more accessible, decentralised production models.

In several instances, sectoral EU legislation even blocks market access for products manufactured using AM technologies. The Medical Devices Regulation, for example, sets major barriers that do not allow timely and full market access for non-personalised medical devices produced at scale using AM. Barriers also exist in other sectors, including construction products and materials, toys, spare parts and others with a particularly negative impact on SMEs, local producers and public services that could benefit from more flexible and decentralised production models.

The European Commission should assess the existence and impact of such legislative and regulatory barriers and address them by revising existing legislation, including by explicitly allowing the placing on the market of products manufactured using AM technologies and at the same time safeguarding high levels of safety, consumer protection, workers’ rights and environmental standards.

The European Union now has an opportunity to secure a leading position in AM and to drive the future of advanced manufacturing on a global scale. Achieving this will require targeted investments, strategic coordination and a strong commitment to translating research into tangible industrial and social impact. We therefore strongly urge you to take decisive action in the next EU R&D framework programme to ensure that AM remains a cornerstone of Europe’s innovation ecosystem contributing to a just green digital transition.

We appreciate your consideration of these proposals and would welcome the opportunity to discuss them further. Please do not hesitate to contact us for additional insights or potential collaboration opportunities.

Sincerely, the undersigned MEPs

THIS NOT A TOY IT IS A PRE-TOKENIZED PHYSICAL OBJECT

This object is not a toy. It is a 3D-printed, golden-ratio, pre-tokenized*, numbered object.

Beneath the T4H logo on the back, there is a pocket with an embedded NFC tag carrying a unique UID, readable by most NFC-enabled smartphones. Tapping the tag opens a web page with a menu offering information** on:

- the object itself

- a synthesis of regulatory barriers that currently make the commercialization of 3D-printed objects difficult

- a call to action for policymakers

- some information about potential conflicts and grey areas between the GDPR’s right to be forgotten and the use of blockchains to store personal data, even when pseudonymised

- future updates

Making the object a blockchain certified collectible.

It is possible to fully tokenize this object by minting an NFT (Non-Fungible Token) that links its unique NFT UID to a blockchain-based, personal and transferable proof-of-ownership digital certificate. The redirect link will be updated to point to this certificate. In this way, the object becomes a physical non-fungible token: certified, verifiable, and transferable — yet still not marketable as a toy under current EU law. If you are interested, or would simply like to know more, please email me at dario.tamburrano@europarl.europa.eu

* pre-tokenized objects are physical items with an embedded NFC tag, a unique UID and a unique URL already pre-assigned, which initially redirect to a general page until the object is activated and linked to a personal and transferable proof-of-ownership certificate.

** The webpage is currently online but not yet in its final form. It will be completed in January 2026.

MATERIALS. Seat, rims and axles: Bambu lab FDM bioplastic filament (PLA – polylactic acid). Tyres and washers: Bambu lab thermoplastic polyurethane filament (TPU), recyclable. Frame and stand-up: Formlab SLS nylon powder (PA12), recyclable, not surface treated. Screws: steel.

Please avoid contact with liquids and oils. In case of stains or broken parts, please contact: dario.tamburrano@europarl.europa.eu

HOW TO ACTIVATE NFC READER READ THE TAG

The NFC tag you need to read is located under the chassis of the quadricycle, directly below the toys4Humanity (T4H) logo. Do not use the camera to scan the logo – it is not a QR code. Simply bring your smartphone close to that area and the tag will be read automatically (if NFC is enabled). If have any difficulties, you can instead scan the QR code printed on the front sticker of the object’s box. This QR code is also unique and is associated with the same UID and link as your NFC tag.

Android Smartphones – Detailed Instructions

1. Open the “Settings” app on your Android device.

2. Look for “Connections”, “Connected devices”, or “More connections” (the name varies by manufacturer).

3. Find and enable “NFC”. If there is an option called “Tap & Pay”, leave it enabled.

4. Unlock your phone.

5. Bring the “back” or “top-back” of the phone close to the T4H logo area where the NFC tag is located.

6. Your phone will vibrate or show a small pop-up when the tag is detected.

7. Tap the notification to open the link stored inside the tag.

iPhone (XS, XR, 11, 12, 13, 14, 15 and newer) – Detailed Instructions

These iPhones have “automatic NFC reading”.

1. Unlock your iPhone.

2. Hold the “top edge” of the phone near the T4H logo area.

3. A small banner will appear at the top of the screen.

4. Tap the banner to open the link stored in the NFC tag.

The reading works even without opening any app.

Older Smartphones Old models can read NFC tags but require an app.

– Android: https://play.google.com/store/apps/details?id=com.wakdev.wdnfc;

– iPhone: https://apps.apple.com/be/app/nfc-reader-writer/id1527949024

Useful Tips

– You don’t need to touch the tag; just bring the phone very close.

– Move the phone slightly if it doesn’t read immediately.

– Metal or thick cases may interfere with NFC.

– Make sure the link begins with “https://” to open correctly.

– NFC works only at very short distance (1–2 cm), this is normal.

Content coming in January–February 2026.

Legal issues relating to potential conflicts and grey areas between the GDPR’s right to be forgotten and the use of blockchains to store personal data, even when such data are pseudonymised.